LISTENING

STUDY Question 40:

How do alternative fibers compare to tree fibers on

environmental impacts?

General

Comments

Yield per Acre/Over Time

Impacts on Water, Energy, and Pollution

Pollution

from Pulp Processing

Energy

Bleaching

Need for Pesticides

and Fertilizers

Soil Impacts

Use of Land

General

Comments

LISTENING STUDY: Several comments point out the complexity

of this question.

It's

almost impossible to make such comparisons. We prioritize

the fibers based on their overall environmental impact:

- Combination

of ag residues to reduce the waste stream and post

consumer waste,

- Behind

that is deinking of preconsumer papers,

- Next

are sustainably harvested virgin fibers,

- Behind

those is tree fiber and agricultural fiber grown in

sustainable ways.

It's hard to make

across-the-board statements. If you have a responsibly

managed farm for on-purpose crops versus FSC-certified

forests where the offcuts are used for pulping, both

are good. Sure, it begs the question: Which is better?

But both scenarios are great. The answer depends on

circumstance: currently, it's easier to get low impact

agricultural fiber than FSC off-cuts. However, it's

easier to take advantage of FSC certified woods, because

the systems are already set up for pulping wood. -

Jeff Mendelsohn, President, New Leaf Paper

"Alternative

Fibers" is a very broad category. It may be so broad

that it will create confusion in the analysis being

performed. There are very big differences between the

various straws, corn stalks, cotton, kenaf, flax, bamboo,

arrundo donax, etc. While it may be useful to categorize

alternatives by various characteristics, it may be more

useful to rely upon the "Search for New Fiber Crops"

work of the USDA, wherein over 500 "alternative" fibers

were evaluated and categorized. - Tom Rymsza,

President, Vision Paper

It

depends on many factors. It's not a black and white

comparison. There are many different tree free fibers

just as there are many different trees used for papermaking.

There are different processing and manufacturing processes

and different end use applications. Trees are grown

differently, with different inputs depending on where

they come from. The same is true with agricultural fibers.

They all have such different fiber lengths, amounts

grown per acre, ways they are processed from the farm

gate to the pulping mill.

There are too many

variables to do anything close to a life-cycle analysis

between "ag fibers" and "tree fibers." Now, if you take

two specific cases and directly compare them, you could

complete a good study. Something that would compare

a specific fiber grown in a specific place with specific

conditions, processed in a specific way for a specific

paper. Then you could compare accurately and with certainty.

Many times we try

to bring it down to science and math - to quantify which

is "better" once and for all. For me and many others,

it's much more simple. We see forests cut down to make

paper and we don't like it one bit. Our forests are

being destroyed and replaced with tree plantations,

while the pulp and paper industry and the forest products

industry is telling us that they are "reforesting."

Well, they're not. They're just planting trees for the

sole purpose of cutting them down again to make more

paper. - Peter Hopkins, Environmental Papers Consultant

for Crane Paper Company, Gargan Communications

Compared

to wood-based papermaking, the information available

on this topic is limited. In the U.S., we only can draw

conclusions from a small number of pilot stage projects

and an even smaller number of commercial operations.

- Environmental Defense Fund Paper Task Force, White

Paper 13, Non-Wood Fiber Sources

A

Ph.D. candidate at the Yale School of Forestry set out

to answer this question and he gave up after several

years of research.

One simplistic answer

is to put ag-residues in the same category as recycled

fiber, as providing the highest and best use due not

only to displacing virgin wood fiber but also providing

a higher and better use compared to burning field crop

stubble. Like recycled (except for high grade white),

residues may not have the highest fiber quality (except

maybe with flex and hemp residues). This is what I mean

- every time there is a statement about non-wood fibers,

there is an exception.

Considering that

non-wood plant fibers and ag-residues were pulped and

used for paper going as far back as 150 AD, there are

hundreds of sources of non-woods for paper, each with

a rich and diverse history that can be explored depending

on where one needs the fiber and what the final product

needs to be. People point out the negatives about monoculture

component of a dedicated fiber crop, such as kenaf,

but it is important to remember that a lot of farmers

want crop rotation opportunities. - Jeanne

Trombly, Fiber Futures

Despite

the fact that I wrote this question for Conservatree

when we first started the Listening Study, and that

the wording represents how environmentalists and paper

purchasers often initiate the discussion, it really

is not the most helpful framing of the issue in trying

to reach a practical answer. There are so many different

possibilities for plants that can be used for nonwood

paper fiber and each is an individual case, complicated

by the fact that geographic region, climate, soil quality,

agricultural practices, governmental subsidies, societal

customs, and so many other factors also further individualize

each case, that there is no one right answer. In addition,

some nonwood fibers may be great environmentally but

lousy for papermaking or otherwise undermine the sustainability

of the system. So I appreciate all the information that

respondents have brought to this question, fleshing

it out with a great deal of both nuance and detail.

I do think that

it would be good to develop more fiber options for papermaking

in order to take some of the pressure off forests, although

I expect that they will exist along with forest fibers

in most cases for a long time to come. I am most focused

on the practical and implementable, not just the theoretical.

It takes such enormous effort and dedication to prevail

with any kind of alternative to the huge, long-term

investments and established system and sub-systems of

using forest fibers for paper that I want to cut to

the chase: What fibers best fulfill all the steps that

are necessary to create a viable new paper; who is willing

to put in the time, money and dedication to develop

it; and how can we create something good and real in

the present or the near future instead of waiting endlessly

for perfection. - Susan Kinsella, Conservatree

LISTENING

STUDY: Some identify different interests based on specific

relationships to the question.

Interests

and perspectives vary by constituency. Some members

of the environmental community identify the use

of non-wood fibers in paper as a way to preserve natural

forests. These constituencies strongly support the use

of annual crops, such as kenaf and hemp. Unlike trees,

these crops are grown and harvested on a yearly basis.

Some supporters claim that kenaf and hemp produce more

usable fiber per land area than trees, are naturally

pest-resistant and can be grown without use of large

amounts of herbicides and fertilizers. They further

point out the potential for non-woods to be pulped without

sulfur and bleached without chlorine. Supporters of

bioregionalism consider non-woods as an opportunity

for small-scale pulping close to areas of fiber production,

thus reducing transportation needs and aiding local

communities.

In contrast, the

paper industry, as represented by the American

Forest & Paper Association, compares non-wood pulping

with prevailing large-scale wood kraft pulping operations.

From that perspective, the widespread utilization of

non-woods constitutes a fundamental change in the industry's

raw material supply and procurement infrastructures.

Individual paper companies in areas of wood shortage,

however, may explore non-wood fibers to expand their

fiber supply. Non-wood industry experts see the highest

current potential in agricultural residues, i.e. by-products

of the production of food and other crops, because of

their immediate availability and relatively low cost.

Farmers are

interested in both annual crops and agricultural residues

as additional income sources. Governments in the U.S.

and Europe are interested in curtailing surplus grain

production by encouraging farmers to grow non-food crops

on agricultural land. Annual fiber crops are considered

attractive rotational crops. Using agricultural residues

would allow fiber production without additional land

use. - Environmental Defense Fund Paper Task

Force, White Paper 13, "Non-Wood Fiber Sources"

Eliminate

paper manufactured solely of virgin fiber and fundamentally

reduce reliance on virgin tree fibers. . . . Increase

the use of other recovered materials (e.g., agricultural

residues and pre-consumer recycled) as a fiber source

in paper. . . . Use alternative crops for paper if comprehensive

and credible analysis indicates that they are environmentally

and socially preferable to other virgin fiber sources.

- Environmental Paper Network, "A Common Vision for

Transforming the Paper Industry," November 20, 2002

"We

think finding a replacement for wood fiber is a problem

that does not need to be solved," John Mechem of the

Washington-based American Forest and Paper Association

told Well Journal. - Jim Motovalli, "The Paper

Chase"

Overall,

the dominance of the wood-based industry perspective

and the associated research corpus has strongly tended

to overwhelm the debate as it has emerged and to claim

the benefit of the doubt. . . . an important example

of how a conventional wood-based perspective could undermine

the nonwoods idea before it could even be argued.

- Maureen Smith, The U.S. Paper Industry and Sustainable

Production

LISTENING

STUDY: Some responses indicate differences between types

of nonwood options.

There

are three broad categories of fibers: dedicated fiber

crops, agricultural residues and industrial residues.

There is a need

for a complete life cycle analysis of both agricultural

residues (e.g. cereal straws) and dedicated fiber crops

(hemp, flax, kenaf)to determine the environmental impacts.

Industrial residues,

byproducts of textile production (rags) though limited

in volume would have a distinct positive environmental

advantage over wood. - Living Tree Paper Company

For

over 1700 years paper was entirely made from a variety

of non-wood fibres, yet today the vast majority is produced

from wood. There are three main categories of non-wood

fibres which are used to make paper:

- Crops

purpose-grown for fibre production such as hemp, kenaf,

jute and flax;

- Agricultural

residues such as cereal, rice straw and bagasse from

sugarcane processing; and

-

Naturally occurring uncultivated crops such as wild

grasses, sisal, and bamboo.

- IIED 1996, Towards A Sustainable Paper Cycle

Nonwood plant fibers suitable for papermaking

. . . can be placed into four general categories of

sources:

-

Agricultural residues,

- Nonwood

fiber crops, or industrial fiber crops,

- Wild

plants,

- Industrial

or post-consumer textile and cordage wastes (e.g.

pure cotton or linen textiles, garments, and manufacturing

wastes, cotton linters, which are a byproduct of cotton

ginning, old rope, and many others).

- Maureen Smith, The U.S. Paper Industry and Sustainable

Production

LISTENING STUDY: Some present a general overview

of the issues, both pros and cons.

First,

I believe that many ag fibers are byproducts so they

have the benefit of being secondary fibers, unlike trees

which are harvested for fiber as the primary use.

- Jeff Lindenthal, President, Green Field Paper Company

Tree

free papers have the advantage of offering the consumer

an alternative paper. The impact of tree based papers

is a widely publicized problem focused around issues

such as deforestation. Tree free papers, however, change

the focus of the impact to issues such as transportation.

Some of the potential advantages of these alternative

sources consist of: less energy required for fiber processing,

decreased production time, and increased yield. However,

when considering these alternative sources potential

disadvantage include excessive water usage, increased

pesticide and fertilizer demands, transportation impacts

and price. - Green Seal, Choose Green Report:

Alternative Fiber Papers

Using

agricultural fibers in place of tree fiber is detrimental

to the environment. Even some of the most intensively

managed forests are much more biologically diverse and

hospitable to surface waters, soil, and wildlife, and

they require far less chemical treatment than annual

agricultural crops. By definition, annual crops like

kenaf must be re-established every year, and that means

at a minimum the soil has to be disturbed and chemicals

applied 25 to 30 times more than the equivalent tree

stand for roughly the same fiber yield over 30 years.

While managed forests are entirely hospitable to biodiversity,

wildlife and endangered species, alternative fibers

are agricultural crops, which means they're monocultures

requiring the near eradication of any competing plant

or animal species. - International Paper

High

quality paper can be made from agricultural fiber crops

such as hemp and kenaf, and from crop residues of wheat

or other cereal grains. In some cases, and particularly

those involving crop residues, there are environmental

advantages of non-wood paper. However, there are substantial

environmental costs of producing dedicated fiber crops

that must be considered when comparing paper made from

these vs. traditionally used wood fibers. When all environmental

impacts are considered, it is debatable whether tree-free

paper made of dedicated crops such as kenaf and hemp

is environmentally better than paper made of wood.

- Dr. Jim L. Bowyer, et al, Dovetail Partners

There

are advantages and disadvantages in using non-wood fibres

for paper-making compared to wood. There is no strong

environmental case for supporting non-wood fibres. With

existing agricultural practices and current processing

and chemical recovery technologies, non-wood fibres

are generally more polluting than wood, although less

energy is required to pulp the fibres. There is no doubt

that increased utilisation of non-wood fibres would

reduce the need for wood. Whether this offers any benefit

depends on the sustainability of wood production (or

the potential for improvement). The effect on incentives

for keeping land under forest cover also needs to be

considered. - IIED 1996, Towards A Sustainable

Paper Cycle

With

some 60-65 million acres of farmland presently idled

each year, at a taxpayer cost estimated at up to $15

billion, the subsidy reducing potential of alternative

cash fiber crops is . . . compelling. - Maureen

Smith, The U.S. Paper Industry and Sustainable Production

The

Agricultural Research Service of the U.S. Department

of Agriculture (USDA) conducted an extensive study of

500 plant fibers as alternatives to wood in pulp and

papermaking in the late 1950s and found kenaf to be

the most promising annual fiber crop. - Environmental

Defense Fund Paper Task Force, White Paper 13, Non-Wood

Fiber Sources

The

advantages of alternative fiber paper are many. "Under

favorable conditions, kenaf can be several times more

productive than trees on a per-acre basis," says fibers

expert E. L. Whitely. "Kenaf dry material could be produced

at about half the cost per unit of producing pulpwood."

Kenaf paper can also be produced without chlorine bleaching,

advocates say. A Technical Association of the Pulp and

Paper Industry (TAPPI) study called "A Search for New

Fiber Crops," demonstrated that alternative fibers require

less energy and chemical use in processing than standard

wood sources. According to the "Using Less Wood" fact

sheet, energy use can be cut by 30 percent in the mechanical

pulp and refining process with alternative fibers.

- Jim Motovalli, "The Paper Chase"

The

kenaf industry wants to take paper-making away from

loggers and hand it over to the kinds of farmers who

are now leaving the land in droves. Instead of paper

being made by large international conglomerates, they

see it being made by family farmers, people with an

investment in the community and kids in the schools.

"It will be a low-input crop," says [Tom] Rymsza [of

Vision Paper]. "It doesn't need much in the way of pesticides

and herbicides because bugs don't bug it, and it outcompetes

most weeds." - Jim Motovalli, "Pulp Friction:

Debating the Paper Alternatives"

LISTENING

STUDY: Many responses compared nonwood fibers to forest

fibers based on specific factors.

Growth

in paper and paperboard consumption in the developed

countries continues at the rate of 2 to 3% annually.

Most of the papermaking fibres are sourced from wood

harvested from the primary forests. Because of economic

greed, the accessible supplies have diminished considerably

during the past 40 years. The demand to increase forest

harvesting rate remains unabated. Culturally-valuable

and ecologically-important forests are being destroyed

unnecessarily.

It is timely to

re-examine the supply of papermaking fibres from a zero-base

viewpoint, without technical prejudice. The obvious

sensible approach is the reinforcement of the basic

tenet: Reduce, Reuse and Recycle, and with the addition

of a "4th R". The fourth "R" is replacement of traditional

virgin wood fibres with other fibres. Replacement with

agricultural cropping residues in paper manufacture,

in conjunction with "reduce, reuse and recycle" practices

would have a significant impact on "saving trees."

- Al Wong, "How Many Trees Can Be Saved?"

The

most important factors in assessment of agricultural

fibers in paper making is how to define the agricultural

fibers. There are several interest groups whose interests

are different - for example in kenaf, hemp, straw, etc.

The general classification that we or I would apply

is first, primary fiber (on-purpose crops) such

as Kenaf, cotton, etc. and, second, by- or co-products,

such as straws and sugar cane bagasse that are a secondary

or by-product of agriculture. Therefore, it depends

upon the classification, the yield could be different.

For example, kenaf is considered as a good virgin fiber

with yield of about 8 tons per acre, but this figure

could be misleading because kenaf will grow in Canada,

but very poorly. Hemp can grow almost anywhere but many

countries prohibit growing hemp. Most of the primary

fibers have higher yield per acre per year than wood

fibers. - James S. Han, Research Chemist, USDA

Forest Service Forest Products Laboratory

Nonwood

and wood fiber crops, used for similar grades of paper

and grown under similar conditions, generally yield

roughly the same amount of paper-making fiber per hectare

(original quote from Atchinson 1994). Hence, there does

not seem to be any benefit to annual crops in terms

of production per acre of land. - IIED 1996,

Towards A Sustainable Paper Cycle

The

only way to answer this is to specify what kind of tree/wood

fiber compared to what kind of non-wood fiber, where.

Even in comparing

the same fiber, such as wheat straw, one may have drastic

variations in fiber yield. The density of wheat grown

in eastern Washington is 4x that in Kansas, for instance.

This is due to climate conditions and soil quality.

With bamboo, there are over 1000 varieties that will

have a different yield per acre. Flax grown for linen

grows much higher than the seed kind, yet the seed kind

yields a beautiful fiber. - Jeanne Trombly,

Fiber Futures

This

section focuses on regions where land could be used

to grow either annual fiber crops or trees. To

reduce pressure on natural forests and other rare or

declining natural communities, we need to obtain fiber

from less ecologically sensitive land. The question

we explore in this section is whether this land should

be used to grow annual crops, such as hemp and kenaf,

or trees.

Supporters of annual

crops for paper production claim two environmental benefits

of using non-wood fiber rather than wood fiber in paper.

They claim that (1) annual crops grown for papermaking

generally produce significantly higher yields of fiber

and pulp than do trees; and (2) such crops require lower

agricultural inputs such as fertilizers and pesticides.

The validity of these claims depends on several variables,

including the type of non-wood fiber and the type of

paper being produced. In assessing these claims, it

is appropriate to compare annual crops to wood plantations

rather than to natural forests because landowners essentially

choose between planting annual fiber crops or planting

trees to provide fiber for paper. It is also important

to compare not only fiber yields, but also the

yields of pulps made from the various fibers.

The pulps being compared also must be functionally

equivalent, that is, they can be used in the same

papermaking application(s). - Environmental

Defense Fund Paper Task Force, White Paper 13, "Non-Wood

Fiber Sources"

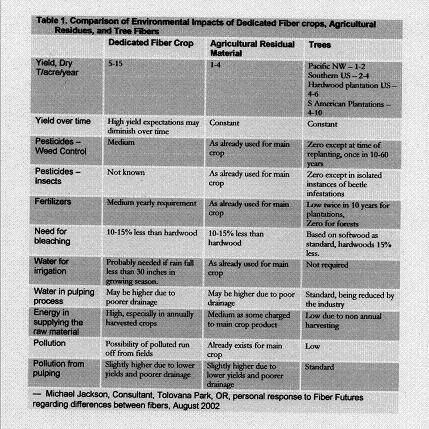

Click on table for larger version

SUMMARY

OF ENVIRONMENTAL FINDINGS

Annual

crops

Whether there are environmental benefits from

using annual fiber crops to make paper depends on several

factors.

- In

regions where tree plantations do not exist or are

not economically viable, growing annual crops for

paper may provide an additional source of fiber. Hemp

cultivation may increase the fiber supply and papermaking

capacities of these regions given its broad geographic

range (although it is illegal to grow hemp in the

United States today.)

- In

regions where landowners can plant trees or annual

crops for fiber, planting trees usually results in

pulp yields in the same range as those of kenaf or

hemp. We did not find evidence to support the markedly

higher yields frequently attributed to annual crops.

-

Yields of whole-stalk kenaf mechanical pulps are

about 60% higher than those of mechanical pulps

made from plantation-grown Southern pine.

-

Yields of kenaf and hemp bast fiber chemical pulps

are lower than that of plantation-grown Southern

pine bleached kraft pulp, with yields about 70%

and 50%, respectively, of that for Southern pine.

- Land

requirements to produce fiber for use in printing

and writing paper are somewhat higher for paper

made from chemically-pulped kenaf bast fibers

or from a combination of bast and core fibers,

than for the combination of softwood and hardwood

bleached kraft pulps typically used in wood-based

paper.

-

On average, pesticide and fertilizer use are lower

for trees than for either kenaf or hemp.

- Annual

fiber crop fields can be expected to provide less

water quality protection; plant and animal habitat

and overall species diversity; and recreational value

than do tree plantations.

-

Environmental Defense Fund Paper Task Force, White

Paper 13, "Non-Wood Fiber Sources"

Back

to top

Yield per Acre/Over Time

| Table

2. Fiber and Pulp Yields of Various Fiber Sources

|

| Plant

|

Fiber

yield

|

Pulp

yield

|

|

(tonnes/year/ha)

|

(tonnes/year/ha)

|

| Scandinavian

softwood |

1.5

|

0.7

|

| Fast-growing

softwood |

8.6

|

4

|

| Temperate

softwood |

3.4

|

1.7

|

| Fast-growing

hardwood |

15

|

7.4

|

| Wheat

straw |

4

|

1.9

|

| Rice

straw |

3

|

1.2

|

| Bagasse

|

9

|

4.2

|

| Bamboo

|

4

|

1.6

|

| Kenaf

|

15

|

6.5

|

| Hemp

|

15

|

6.7

|

| Elephant

grass |

12

|

5.7

|

| Canary

grass |

8

|

4.0

|

| Source:

Pande 1998 |

The

yield data [in the White Paper] indicate that, on average,

annual fiber crops produce higher yields than softwood

plantations, but not hardwood plantations. -

Environmental Defense Fund Paper Task Force, White Paper

13, "Non-Wood Fiber Sources"

LISTENING STUDY: Several experts specifically argue

about the yields of kenaf vs. wood. Some present data

they consider definitive, while others offer explanations

for legitimate variations. The basis for calculations

in a key reference document is challenged.

We

would argue that where there are not local sources of

wood that are accessible for harvesting, the use of

agricultural fiber, whether it is ag residues or annual

crops, may be a reasonable supplement or alternative

to wood fiber.

The question of

yield should be answered by comparing usable pulp yields,

rather than simply biomass or fiber yields per acre.

For mechanical pulp applications, virtually the entire

crop can be used. However, chemical pulping processes

result in far lower overall plant usage. A lot of the

initial literature on nonwood fibers compares only biomass

or fiber yield and not usable pulp yield. In our assessment,

the pulp yields for nonwoods may be lower, the same

or higher than for wood, depending on the application

and pulping process used. In particular, when the whole

stalk of kenaf is used, as should occur in a mechanical

pulping system, usable pulp yields are on average higher

than those for loblolly pine in the South. Typically,

plantation-grown loblolly pine has the highest usable

pulp yields of the trees. On the other hand, when a

chemical pulping process is used, for wood or nonwoods,

usable pulp yields are lower for kenaf or hemp relative

to yields from loblolly pine. On average, kenaf pulp

yields are 70% that of the bleached southern pine pulp.

Hemp pulp yields are on average 50% of the southern

pine in a chemical pulping system.

Another way to compare

yields is based on the equivalent land requirement:

How much land is necessary to grow the equivalent amount

of pulp? These comparisons depend on the usable pulp

per acre estimates. It follows that for the chemical

pulps, a higher land use was necessary for kenaf than

for soft or hardwood. Our estimate shows the required

land use to be 0.59 acres per ton for separated 100%

bast fiber for kenaf, 0.40 acres per ton for a mix of

whole stalk-bast and core fibers, and 0.36 acres per

ton for a typical mix of hardwood and softwood. These

estimates are conservative. - Richard Denison, Ph.D.,

Senior Scientist, Environmental Defense

Environmental

Defense's Paper Task Force White Paper #13, on Non-Wood

Fiber Sources, provides data that many organizations

still use to make decisions and promote viewpoints on

the economic and environmental viability of kenaf fiber

compared to forest and other types of fiber. Yet there

are serious mistakes in White Paper #13's calculations.

When others use these data, they are continuing arguments

based on very basic mistakes.

For example, Table

3 in the White Paper is labeled, "Fiber yields of kenaf,

hemp and plantation woods (bone-dry tons/acre)." In

fact, there is kenaf data and hemp data, but no plantation

woods data. Yet the missing tree yield data is referred

to many times throughout the report.

There are also problems

with the conversion factors listed at the top of the

table. These conversions are important because much

of this type of numeric data from the studies referenced

in the table may be presented in either metric terms

or U.S. terms and therefore must be converted to consistent

measurement. Yet the conversion factors include these

mistakes:

-

A U.S. short ton (2,000 pounds) is described as equal

to 1.1 metric tons (2,20224 pounds), when in fact

a short ton is .9 metric tons.

- The

conversion of tons/acre to metric tons/hectare is

off by a factor of 6.

- A

cubic foot of softwood is represented as equivalent

to 60.30 tons. Think about that. A cubic foot is a

little bit bigger than a gallon of milk. If it was

lead, it would weigh 705 pounds. Three tractor trailers

weigh 60 tons. A cubic foot of softwood does not weigh

60 tons.

- A

cubic foot of hardwood is listed as being equivalent

to 40 tons. First, it's impossible for it to weigh

40 tons. But second, the relative values are wrong.

Hardwoods are denser, therefore heavier, than softwoods.

Results

are further skewed when the report says that you can

only use part of the kenaf plant to make chemical pulp

for high-grade papers. But Environmental Defense's own

report refers to whole stalk chemical kenaf pulp produced

in Thailand in at least three places, contradicting

their own assertion. And conclusions are drawn based

on confusion of pulp yields with raw fiber yields, two

very different types of data.

How can we have

a science-based discussion attempting to arrive at a

well-thought-out comparison of the merits of different

types of fiber if the basic data - and even the basic

conversion factors - are wrong? - Tom Rymsza,

President, Vision Paper

Research results from around the world indicate

that the kinds of kenaf and hemp yields as seen in Table

1 (U.S. hemp average 2.2 tons/acre/year, Non-U.S. hemp

avg. 3.8, U.S. kenaf avg. 6.3) are not attainable without

attention to a number of production factors, including

soil moisture and fertility, competition from weeds,

and problems posed by insects and disease. It appears

that regardless of claims to the contrary, production

of both kenaf and hemp require regular application of

fertilizer and various chemicals, and sometimes irrigation,

similar to other forms of high yield agriculture.

- Dr. Jim L. Bowyer, et al, Dovetail Partners

. . . [T]he amount of land required to produce

printing and writing paper from wood is slightly lower

than that required for kenaf. - Environmental

Defense Fund Paper Task Force, White Paper 13, "Non-Wood

Fiber Sources"

Kenaf yields 2-2.5 tons of pulp fiber/acre/yr

and 6-8 tons of fiber/acre per 4-5 month growing period.

One ton of kenaf has a 52% fiber yield, higher than

the average 45% for trees. Awhile back, International

Paper grew test plots in Texarkana and presented negative

yield results. They yielded only 3-3.5 tons of fiber/acre/yr,

but that was due to poor harvesting methods. -

Tom Rymsza, President, Vision Paper

On

the yields - If you take 100 lbs. Arundo donax, 100

lbs. kenaf, and 100 lbs. wood, kenaf yields about 25

lbs. usable material, wood 44, Arundo donax 49.5 lbs.

- Ernett Altherimer, Founder and Chairman, Nile Fiber

Compared

with trees, kenaf, at 6-10 tons per acre, produces 3-5

times more fiber per acre per year. The yield depends

on the specific "alternative" fiber. The yield for kenaf

is roughly 50%. The yield for trees is about 46%.

- Tom Rymsza, President, Vision Paper

There

are lots of opinions, though not sufficient documentation

on how contradicting claims can be reconciled. For examples,

kenaf advocates will claim that yields per acre of kenaf

are greater than for trees. Wood proponents will make

the opposite claim. Clearly, there are underlying discrepancies

on how we arrive at these numbers. In short, it is impossible

to compare an acre of trees grown in the northwest to

an acre of kenaf grown in the southwest. The different

climates give these areas different growth potentials

for different plants. A true comparison of yields would

look at the growth potential for the softwood and the

kenaf on the same acre of land. - Russell Clark,

Environmentally Preferable Purchasing Program, US EPA

Back

to top

Impacts

on Water, Energy, and Pollution

LISTENING STUDY: Some responses refer to factors

involved in acquiring the fiber, whether through logging

or farming.

Several

initiatives [in the U.S. and other countries] have looked

at utilising waste straw, particularly since a number

of countries no longer allow straw burning. -

IIED 1996, Towards A Sustainable Paper Cycle

Sorghum

is a low input crop (Kent Kaulfuss) - less irrigation

(2/3 less water on average). - Lieberman 1995

In

terms of environmental impacts of growing ag fibers

vs. trees, I don't have specific data. My general impression

is that those sources of cellulose fibers which are

most pure (cotton) compared to those with a lot of impurities

(wood) are much less chemically intensive to process.

- Jeff Lindenthal, President, Green Field Paper Company

Back

to top

LISTENING

STUDY: There are significant

differences in environmental impacts when specific types

of fibers are pulped for papermaking. Many respondents

went directly to evaluating the result of using different

fibers for pulping. While all the factors are inter-related,

some responses bring out details of one over another.

Pollution

from Pulp Processing

There

is uncertainty when comparing the effluent quantity

and quality of tree free versus tree pulping processes

because of mill scale issues. In many cases, non-integrated

nonwood mills are small compared to tree based pulp

mills, and may not possess comparable systems for recovery

or treatment of effluent, in which case effluent quantity

and quality will likely be worse than for a larger wood-based

mill. In a larger mill, recovery of pulping chemicals

and effluent treatment are far more prevalent and economic.

If annual crops are integrated into existing mills that

already have effluent recovery or treatment, they would

be able to take advantage of these technologies and

the result would be very different than for small mills

like those we see in developing countries.

In mechanical pulping

processes, effluent quantity and quality are better

compared to chemical pulping processes, regardless of

fiber source. In our study, the quantity of effluent

from a soda-process kenaf bleached pulp mill should

be comparable to a softwood bleached kraft mill, and

effluent quality should be similar as well. However,

the soda process, which is more common in Europe, is

almost non-existent in the US. For the typical kraft

process applied to kenaf, the effluent flow is almost

twice that of the same process applied to softwood.

Effluent quality should be fairly similar.

A note on the [Paper

Task Force] study: there is a much greater range in

the numbers obtained for wood mill effluent quality

parameters than for kenaf. This may be due to there

being less data for kenaf mills. - Richard

Denison, Ph.D., Senior Scientist, Environmental Defense

Small

mills are preferable for nonwoods because of limited

fiber supply, therefore capital costs are lower. However,

small mills by nature will be more polluting because

chemical recovery does not make economical sense.

The

higher proportion of silica in most nonwood fibers makes

traditional chemical recovery processes ineffective.

This results in a highly polluting effluent and an uncompetitive

production process since the chemicals are not recovered

and cannot be reused. In addition, the cost of installing

chemical recovery systems is prohibitive for most small

mills. This is one of the most serious problems associated

with the use of nonwood fibers compared to wood, although

the small capacity of many non-wood mills means that

the overall impact is relatively low. . . with sufficient

investment, a cost-effective and suitable process could

be developed.

The pollution levels

from non-wood mills can be improved by reducing the

amount of silica going into the effluent, developing

a more efficient chemical recovery system for effluent

with high silica content or introducing an alternative

pulping process where there is less need for chemical

recovery. - IIED 1996, Towards A Sustainable

Paper Cycle

Silica

can pose a significant problem for some agricultural

fibers. Silica accumulates and hardens on machinery

creating the need to frequently stop production and

clean with caustic chemicals. Regularly shutting down

machinery in a pulp mill decreases any chance of creating

an economically viable product. Some agricultural residues

such as straw and corn stalks have high levels of silica.

Kenaf does not contain silica. - Tom Rymsza,

President, Vision Paper

One Indian mill solved silica removal problems

by washing the straw before processing, but they still

had problems disposing of the silica water. -

Atchison 1999

Non-woods generally use less energy and less water

and fewer chemicals for pulping, but the pollution impacts

to recover the chemicals have been a real bugger. Only

now are there actual and affordable chemical recovery

technologies that are emerging out of the laboratory

and just past pilot stage. Once the silica issue is

solved, the resource "footprint" of most nonwoods (cereal

straws, grasses and reeds) will clearly be less than

wood-based pulping. With papermaking there is very little

difference. - Jeanne Trombly, Fiber Futures

Back

to top

Energy

Agricultural

fibers have a slight advantage in energy consumption

and pollution due to low lignin contents, but wood fibers

have high cellulose contents. See below, Table 3. Dimensions

and Chemical Composition of Some Common Straw Fibers

- James S. Han, Research Chemist, USDA Forest Service

Forest Products Laboratory

| Table

3. Dimensions and Chemical Composition of Some Common

Straw Fibers |

| Type

of Fiber |

Cellulose

|

Lignin

(%)

|

Fiber

Dimension (mm)

|

|

Length

|

Width

|

| Cereal

straw |

31-45

|

16-19

|

1.5

|

0.023

|

| Corn

straw |

32-35

|

16-27

|

1.5

|

0.018

|

| Wheat

straw |

33-39

|

16-23

|

1.4

|

0.015

|

| Rice

straw |

28-36

|

12-16

|

1.4

|

0.008

|

| Coniferous

wood |

40-45

|

26-34

|

4.1

|

0.025

|

| Deciduous

wood |

38-49

|

23-30

|

1.2

|

0.030

|

| Source:

James S Han, Research Chemist, USDA Forest Service

Forest Products Laboratory |

The

total energy consumed to produce a ton of whole-stalk

kenaf mechanical pulp is about 35% lower than the total

energy consumed to produce a ton of softwood mechanical

pulp. The total energy consumed to produce a ton of

kenaf soda pulp using an ECF bleaching process is about

37% lower than the total energy consumed to produce

a ton of softwood bleached kraft pulp using an ECF bleaching

process. However, the purchased energy [electricity

purchased off the grid and fossil fuels burned on-site]

consumed by the kenaf soda mill is about 50% higher

than the highest purchased energy consumed by a wood-based

kraft mill. - Environmental Defense Fund Paper

Task Force, White Paper 13, "Non-Wood Fiber Sources"

If you look just at purchased energy, the kenaf

processing uses 50% more. This is because the wood-based

mill generates considerable energy by burning wood-derived

materials that are by-products of the chipping and pulping

process. The wood industry tends to argue this energy

is "free" and even claim that they use less total energy

than nonwood mills. However, the entire tree - both

the part that becomes usable fiber and the part burned

for energy - has to be grown and harvested. Therefore,

any impacts of harvesting and growing trees, including

natural resource depletion or damage, and air pollution

from combusting the wood-derived materials, applies

to this energy source. - Richard Denison, Ph D,

Senior Scientist, Environmental Defense

Summary

of Environmental Findings:

- The

total energy consumed to produce a ton of kenaf mechanical

pulp is about 35% lower

than the total energy consumed to produce a ton of

softwood mechanical pulp.

- The

total energy consumed to produce a ton of kenaf soda

pulp using an ECF bleaching process is about 37% lower

than the total energy consumed to produce a ton of

softwood bleached kraft pulp using an ECF bleaching

process. However, the purchased energy consumed by

the kenaf soda mill is about 50% higher than the highest

purchased energy consumed by a wood-based kraft mill.

-

Effluent flow and quality are similar for the kenaf

and the wood-based chemical pulps.

-

Environmental Defense Fund Paper Task Force, White

Paper 13, "Non-Wood Fiber Sources"

Since

there is no such kenaf soda mill in the world, how can

EDF make this assertion? - Tom Rymsza,, President,

Vision Paper

Back

to top

Bleaching

LISTENING STUDY: The relative need for bleaching

can be determined, in part, by the lignin quantity in

the fiber. Table 4 compares the chemical properties

of various nonwood fibers.

| Table

4. Chemical Properties of Various Nonwoods |

| Fiber

Source |

Alpha

Cellulose (%) |

Lignin

(%) |

Pentosans

(%) |

Ash

(%) |

Silica

(%) |

| Bast

Fibers |

| Jute

(1) |

|

21 - 26

|

18

- 21

|

0.5

- 1

|

<1

|

| Kenaf

|

31

- 39

|

15

- 18

|

21

- 23

|

2

- 5

|

|

| Oilseed

flax tow |

34

|

23

|

25

|

2

- 5

|

|

| Textile

flax tow |

45

- 68

|

10

- 15

|

6

- 17

|

2

- 5

|

|

| Leaf

Fibers |

| Abaca

|

61

|

9

|

17

|

1

|

<1

|

| Sisal

|

43

- 56

|

8

- 9

|

21

- 24

|

0.6

- 1

|

<1

|

| Seed

Hull Fibers |

| Cotton

staple |

85

- 90

|

3

- 3.3

|

|

1

- 1.5

|

<1

|

| Cotton

linters |

80

- 85

|

3

- 3.5

|

|

1

- 1.2

|

<1

|

| Stalk

Fibers |

| Canes

|

sugarcane

bagasse |

32

- 44

|

19

- 24

|

27

- 32

|

1.5

- 5

|

0.7

- 3

|

| bamboo

(wide range) |

26

- 43

|

21

- 31

|

15

- 26

|

1.7

- 5

|

1.5

- 3

|

| Cereal

straw |

barley

|

31

- 34

|

14

- 15

|

24

- 29

|

5

- 7

|

3

- 6

|

| oat

|

31

- 37

|

16

- 19

|

27

- 38

|

6

- 8

|

4

- 7

|

| rice

|

28

- 36

|

12

- 16

|

23

- 28

|

15

- 20

|

9

- 14

|

| rye

|

33

- 35

|

16

- 19

|

27

- 30

|

2

- 5

|

0.5

- 4

|

| wheat

|

29

- 35

|

16

- 21

|

26

- 32

|

4

- 9

|

3

- 7

|

| Grass

|

arundo

donax |

29

- 33

|

21

|

28

- 32

|

4

- 6

|

1.1

- 1.3

|

| esparto

|

33

- 38

|

17

- 19

|

27

- 32

|

6

- 8

|

2

- 3

|

| sabai

|

|

17

- 22

|

18

- 24

|

5

- 7

|

3

- 4

|

| switchgrass

|

43

|

34

- 36

|

22

- 24

|

1.5 - 2

|

|

| Reeds

|

phragmites

communis |

45

|

22

|

20

|

3

|

2

|

| Woods

- for comparison |

| Coniferous

|

40

- 45

|

26

- 34

|

7

- 14

|

1

|

<1

|

| Deciduous

|

38

- 49

|

23

- 30

|

19

- 26

|

1

|

<1

|

| Note:

For well cleaned raw material - the composition

of uncleaned raw material will be different with

respect to pentosans, solubles, ash and silica content

in many cases. |

|

Source: Hurter 2001

|

Most

annual crops, when compared with trees, contain lower

levels of lignin. Since chemical pulping methods remove

non-cellulose components, many annuals can be pulped

using milder chemistry and less energy.

The ability to bleach

a fiber with low or no chlorine depends on the fiber

properties. Al Wong has previously reported that hemp

is difficult to bleach. Kenaf is naturally whiter than

tree pulp and can be bleached in a totally chlorine

free environment. - Tom Rymsza, President,

Vision Paper

On

bleaching, it is generally clamed that agricultural

fibers can have less lignin so less bleach is needed

to get paper white. I haven't seen the scientific studies

demonstrating this, but they're probably out there.

The claim that nonwoods might use less water in the

pulping and bleaching process might have to do with

the type of bleach used. For a smaller run, it might

be more economical to use a more expensive process where

the chemicals are reused rather than thrown out because

it uses less bleach. In this case, the smaller process

may allow a better technology. - Russell Clark,

Environmentally Preferable Purchasing Program, US EPA

The

brightness of rice straw paper is 88 and wheat straw

is 80-85, in comparison to hardwood 85-90, and softwood

88-90. Thus, wood fibers have a slight advantage over

agricultural fibers. - James S. Han, Research

Chemist, USDA Forest Service Forest Products Laboratory

Bleaching

of nonwood pulps, however, typically is easier than

woodpulp and requires fewer bleaching stages and lower

chemical consumptions. - Hurter 1998

Back

to top

Need

for Pesticides and Fertilizers

LISTENING

STUDY: Some argue that agricultural crops require more

pesticides and fertilizers than plantation trees.

We

found relative little data characterizing agrichemical

use on annual crops. The available data indicate that

pesticide and fertilizer usage even for plantation-grown

trees is generally lower than it is for kenaf and hemp.

The main reason for this is that trees are grown on

multi-year rotations with chemicals applied at most

every few years, in contrast to annual crops, where

such chemicals are applied annually. With respect to

pesticide use on annual crops, there is geographical

variation based on endemic pest problems. Fertilizer

input can also vary, but it is important to realize

that fertilizer use and yield go hand in hand. In our

yield estimates, the highest yields corresponded to

the highest fertilizer inputs.

In our comparisons,

a typical pine stand planted on a 25 year rotation receives

8 lb. fertilizer/acre/year. Kenaf received a greater

range and a considerably higher average amount of nitrogen

based fertilizers: from 0-130/150 lb./acre/yr. Most

of the hemp information indicated more than 100 lb/acre/yr.

- Richard Denison, Ph D, Senior Scientist, Environmental

Defense

Most

farmers use pesticides and fertilisers on their non-wood

fibre crops, although it is possible to grow most types

of fibre without those inputs. Amounts applied vary

significantly, as with tree plantations, but generally,

it would seem that approximately the same amount of

pesticides and fertilizers are used on a single rotation

of trees (minimum seven years) as for a single rotation

of agricultural crops (one year). - IIED 1996,

Towards A Sustainable Paper Cycle

Most annual plants need pesticides and fertilizers,

including virgin fibers. - James S. Han, Research

Chemist, USDA Forest Service Forest Products Laboratory

LISTENING

STUDY: There are situations in which each alternative

might use more.

Any farm fiber used for large scale papermaking

will require some level of pesticides and fertilizer.

Since the farmer is harvesting for fiber instead of

fruit or grain, less herbicide and no insecticide are

used for a crop such as kenaf. Agricultural waste fibers

would have a different chemical use profile, since they

are grown for grain or fruit.

EDF and the Paper

Task Force reported in its White Paper #13 that tree

farms used fertilizer at rates between 0-34,000 pounds

per acre per year. Compared to the high- end estimate,

a kenaf field has less inputs. - Tom Rymsza,

President, Vision Paper

LISTENING STUDY: There are also arguments that agricultural

crops used for papermaking require less pesticides and

fertilizers, often because of beneficial properties

of the plants.

There

are specific studies on particular fibers, such as hemp

and kenaf that insist they need fewer chemicals than

wood plantations, which can be resource intensive, depending

on the grower. But again, there are no broad studies

to provide the data that is needed to answer this question.

- Jeanne Trombly, Fiber Futures

[Sorghum is a] fast grower, so less weed competition,

less cultivation requirements. Low pest pressures (both

kenaf and sorghum) - kenaf is host to beneficial insects.

- Lieberman 1995

High growth of above-ground biomass corresponds

to high nitrogen fertilizer uptake … a law of nature.

See for example, my presentation, "Socio-Economic and

Technical Issues of On-Purpose Fiber Cropping and Food

Cropping." - Al Wong, Founder, Arbokem

Currently, the only legal chemical to use on kenaf

is Treflan, made by Dow AgroScience. Though not benign,

it is generally safer than others. Most kenaf fields

do not use fertilizer, as kenaf is ideal to rotate in

after soybeans. No post-planting herbicides are needed.

The fast growing tall stalks shade out other plants.

Application would be too difficult anyway because the

plant grows too tall. - Tom Rymsza, President,

Vision Paper

Back

to top

Soil

Impacts

Arundo

donax is a carbon sequestration giant. It takes in carbon

and effluents and stores them in the leaves, stems,

etc. … Compared with wood it is 90% more efficient at

sequestering carbon. Arundo donax enhances the soil

by processing toxic chemicals to an inert form. For

example, Alabama had a five-year drought but everything

growing around the Arundo donax did fine. Arundo donax

uptakes toxins from air and soil and every kind of effluent

from the air. - Ernett Altherimer, Founder

and Chairman, Nile Fiber

Kenaf's long roots remove salt deposits in the

soil and can be used as an excellent rotation crop for

improving the soil … and can pull up lost nitrogen leached

farther down in the soil (originally quoted from

Steve Shaffer of California Department of Food and Agriculture).

- Lieberman 1995

The

disturbance of soil, which has carbon loss implications

relevant to global warming, is typically much higher

for agriculture than for silviculture. The frequency

of entry for tree plantations is lower, and the impacts

of such entries are less intense, than for annual crops.

There are lower-impact crop practices such as conservation

tillage, though we are unaware of data as to how often

these are applied on kenaf and hemp fields. Soil conservation

is an important consideration because it also has erosion

and runoff rate implications, a particular concern when

agrichemicals are applied. - Richard Denison,

Ph.D., Senior Scientist, Environmental Defense

Before we advocate the use of a particular non-wood

fiber from an identified area, we always pull in the

expertise of a soil scientist. Some soils need the biomass

from ag-residues. Other soils cannot absorb the density

of material. With wheat straw, many Agriculture Extension

representatives and farmers are discovering that they

prefer not to till the straw back into the earth because

that exacerbates erosion. This is why they prefer to

burn it, and it would point to another advantage for

removing the straw for a fiber use. - Jeanne

Trombly, Fiber Futures

The

specific blend of fibers in each material, coupled with

how the product is made, affects the sustainability.

Diversity is the key for an economically and strategically

positioned fiber supply. In theory, the wear and tear

on the land (topsoil) over ten years growing trees would

be less than an annual crop, while the production of

pulp from trees would require more energy and water

based on lignin content, etc.

Perennials such

as Arundo donax and switchgrass have the same arguments.

You've still got a tractor going in every year for harvesting.

This causes more damage to the soil than trees. Generally,

the harvesting, baling, etc. … are never factored in

comparisons between agricultural fibers and trees. Arundo

donax would be somewhere in between an annual and a

tree. While you have to cut it out every year rather

than every 12 or so years, it has a lower energy consumption

in the pulping process. You only have to handle the

tree once every life cycle, but the entire life cycle

of the tree is always going to expose the soil to the

elements for the least amount of time. Annual crops

have the greatest mean exposure to the elements. Next

are the herbaceous crops.

If we hold Arundo

donax as a token fiber, as the U.S. Dept. of Energy

has done with switchgrass, then we shoot ourselves in

the foot, because diversity is the key. Each fiber source

has a growing condition and other environmental factors

that make it superior in a given application.

- Peter A. Nelson, President, AgroTech Communications,

Inc.

Back

to top

Use

of Land

The forest plantations that cover ancient forest

soils are not the answer.. These plantations tie up

useful land, and after only a few rounds, leave the

soil decimated. We cannot pretend that we will turn

these areas back into forests. Kenaf offers us a viable

alternative. Kenaf, unlike tree plantations, can be

integrated as a rotation crop. Plantations tie up land

for six to 17 years, while a kenaf crop reaches a harvestable

height of 12 to 18 feet in only 150 days and yields

five to 10 tons of fiber per acre annually (as opposed

to two to three for southern pine). - David

Brower, "Kenaf: A Tree-Free Alternative"

Eradicating creek beds of the non-native (Arundo

donax) has provided some production material and the

seed stalk. We harvested rhizomes to cultivate. We are

also researching stem cell cultivation. - Ernett

Altherimer, Founder and Chairman, Nile Fiber

The Stockton Pacific Enterprises pulp mill [in

Samoa, California] says it has abandoned plans to grow

a giant reed in the Central Valley and ship it to Humboldt

County to make wood-free pulp. The pulp company also

will not ship the invasive reed, Arundo donax, from

sites in Southern California where it is being eradicated

[because t]he costs of moving a raw material over such

long distances are too high . . . That may be just as

well, according to some who worry that the giant reed

could become a giant pest, like it has as far north

as the Russian River. The reed grows up to 30 feet tall,

and spreads when floods break off pieces of cane, which

root downstream. It isn't thought to sprout from seed.

. . . It was also

planted around bridge abutments and erosive areas to

shore up problem spots, but it has spread like wildfire.

Experts say an infestation in the North Coast's salmon

streams could be disastrous. Stockton Pacific was Samoa

Pacific when the Arundo plan was hatched in 2002. That

former company planned to ship the reed north in tightly

covered trucks. But it takes only a little Arundo to

spawn a big problem. - John Driscoll, "Pulp

Mill Forgoes Wood-Free Pulp Plan"

LISTENING STUDY: Further debates about the appropriate

land-use of trees vs. different kinds of agricultural

crops are presented in Question 42.

Back

to top

|